|

Digital Instrument Cluster

A How-To Guide For The DIYer

I had been attempting to

work with Nordskog to build a digital instrument cluster for the

Probe but the company went under in the typical corporate

fashion. So I went looking to see if I could find a

suitable digital cluster which could be reasonably easy to

install. I found several possibilities such as the Ford

Tarus, Ford Windstar, Mercury Villager and Buick Riviera.

|

|

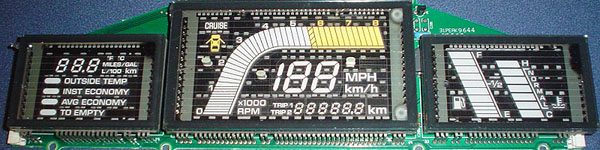

The Cluster:

I

chose the Mercury Villager cluster from the 1990's because as

seen to the right -it is very similar in size and shape.

Also it had the highest reading tachometer out of all the other

possibilities. It will go to 8k RPM which is a good limit

for our engines.

The

Villager is a 6-cylinder which makes it a good candidate because

the tach will read the correct RPM. Also -the temperature

sensor has the same signal output as our Probe sender

does. So the Tach and temperature are no-brainers.

|

|

|

| The

How-To:

|

| Here is the Villager cluster

when lit up: |

|

|

The Outside Air Temperatrue

(OAT) is a nice "gee-wiz" feature but is really

un-necessary and the KL cars do not have a fuel flow

signal from the ECU to make use of the fuel economy

computer function. So since the displays are

individual tubes it is easy to remove the un-needed

display to the far left. This will make room for

other more important guages such as oil pressure or O2

wideband, etc.

|

|

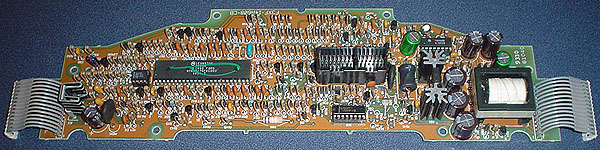

| Below is the main printed

circuit board (PCB) that does all of the calculations and

conversions for the displays. It is not necessary to

do any modifications to this board. |

|

|

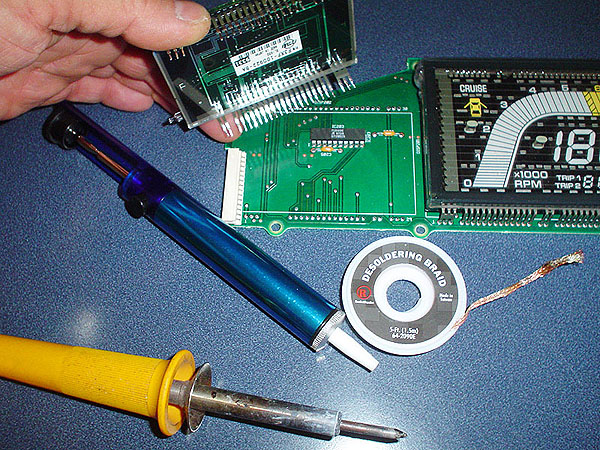

These are tools that you

would need to remove the un-needed display. The blue

thing is a solder sucker and works very good to remove the

molten solder from in the holes around the pins. You

can also use de-soldering braid to suck up some of the

solder.

|

|

|

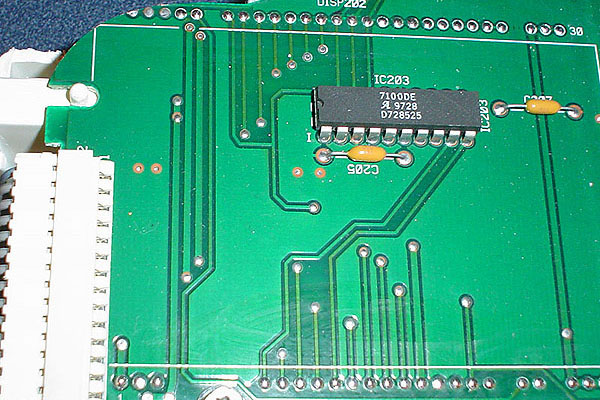

Here is the display board

with the tube removed. Notice how I filled the holes

with solder after the display tube was removed. This

is to keep the foil tracings connected from one side of

the board to the other. This is a dual sided PCB

-meaning that there are traces as seen in this photo below

-also on the reverse side but just with a different

layout. This is called very good usage of all

available real-estate. There are too many circuit

paths to be able to lay out the entire circuit on only one

side of a board so they also use the back side. If

you do not fill the holes after removing the tube then you

may be creating an open in a circuit that lights one of

the display tubes that you do want. So fill them

well. Also notice in the photo below how the corner

has been rouned off. This is for a clearance

issue. The last three holes on the left are only

used to help hold the tube in place. They do not

have any tracings on either side of the board so it

doesn't matter if you cut into them some as I have

done. Just be careful when rounding the corner that

you do not remove any tracings near by. The large

green areas are typically grounds and it doesn't hurt any

to cut into them some either.

|

|

|

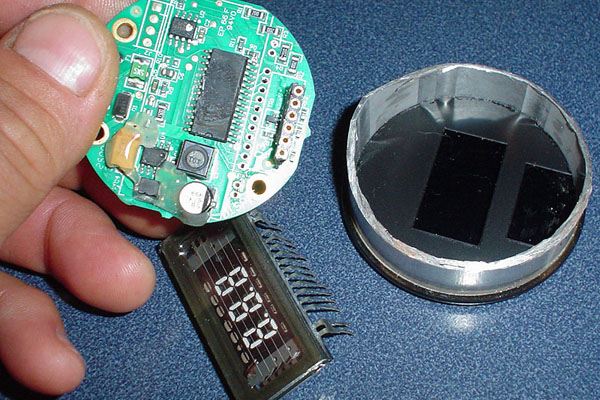

Here is a VFD type oil

pressure gauge and I have cut the casing carefully with a

Dremel and removed the display to mount it to the display

PCB while mounting the circular PCB shown somewhere

remotely with a ribbon cable connecting the two.

|

|

|

Now it is time to do some

plastic welding to join the PGT cluster housing and the

Villager one. I cut both pieces so that I have the

forward rim of the PGT cluster and the back shell of the

Villager since it has all of the mounts for the PCB's.

|

|

|

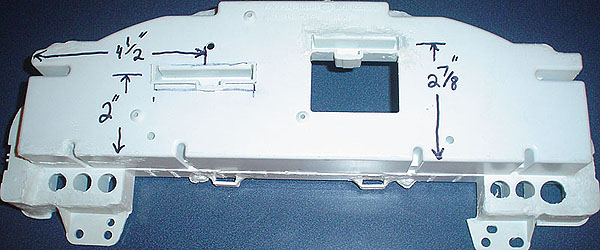

Here is the finished welded

shell with the PGT connector coves welded in place to make

it so that the stock PGT connectors will still plug into

it and keep it totally plug-n-play. The

measurements are for locations for the coves that miss all

essential electronic components inside the housing.

If you do not place the coves in these locations then you

could end up with some bent over components when you fully

assemble the unit.

|

|

|

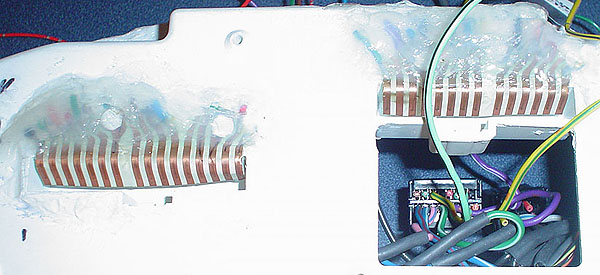

Here is how I melted some

stubs of plastic to hold in the foil traces from the back

side of the PGT cluster for soldering wires to. I

drilled small holes just to the ends of the foil traces

where it was cut so that the holes will stabilize the

wires. once you weld on this foil -the plastic

in-between WILL MELT! So after you have them all

soldered and the plastic is missing between them all then

you need to glue everything in place with silicone glue as

shown. This secures everything nicely and the PGT

plugs will now plug right in just as they did with the OEM

piece.

|

|

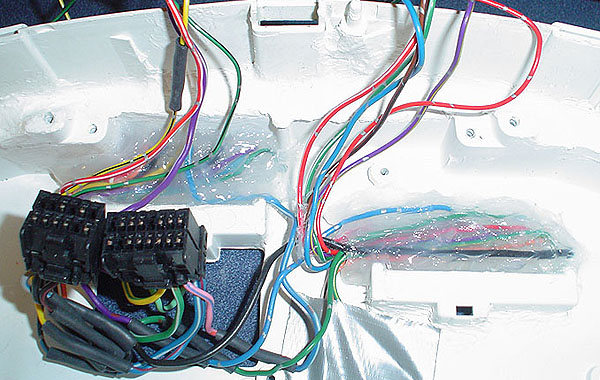

| Here is the inside view and

the Villager plugs when spliced in. They will

connect right up to the Villager PCB nicely inside the

housing. Click here

for the Villager wiring diagram. |

|

|

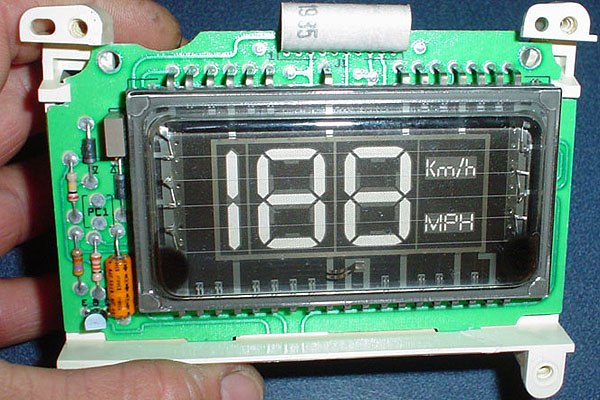

This is a VFD display for

speed only and it comes from an eighties model

Lincoln. I plan to make a Head Up Display HUD from

this one. A HUD is where the speed is

projected/reflected onto the windshield so that you can

see it in front of you without taking your eyes off the

road. Several newer cars are coming out with this

option.

|

|

|

I have been running the

display for a while installed within the car. So far

- the test results are fantastic. It took a bit to

get the fuel tank sending unit tweaked for correct

readings but after that - it is so linear that it appears

to be more accurate than a stock Probe fuel guage.

The shot below was taken using a flash. The flash

goes through the 1/8 inch thick blue Plexiglas filter that

I have cut from a sheet and thus shows the display tubes

behind the filter. The Plexiglas must be cut with a

rotary drill type cutting tool. Any sawing type tool

will cause the Plexiglas to crack.

|

|

|

This second photo was taken

without a flash to show more closely what the display

looks like (without the over-exposure blur of this

one). When you shoot a light source it can often

cause the blurring effect. But at least you can see

close to what it looks like here:

|

|

|

These types of digital

clusters can be fit similarly into other cars such as the

Mazda MX6 or 626. I know of a few people who have

started a similar conversion for the 626 so when they are

done -perhaps we can post photos of those as well.

The numbers up in the top right hand corner are my oil

pressure.

|